Aluminium and Steel Can Baler Machine

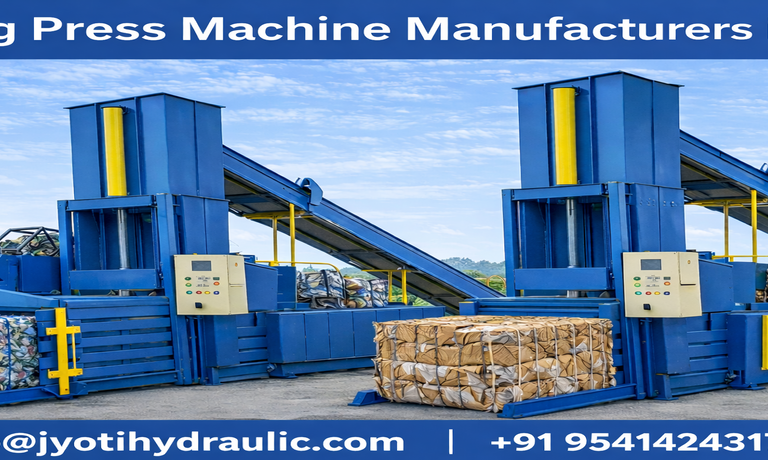

An Aluminium and Steel Can Baler Machine is a specialized hydraulic compaction system designed to compress large quantities of used aluminium cans, steel beverage cans, tin containers, and lightweight metal packaging waste into dense, easy-to-handle bales. This machine plays a vital role in recycling industries, bottling plants, waste management facilities, scrap yards, beverage production units, and municipal waste-collection centers where metal cans accumulate rapidly. Built for high-speed operation and long-term durability, the baler uses powerful hydraulic force to reduce the volume of cans by up to 80–90%, enabling efficient storage, handling, and transportation. Manufacturers like Jyoti Hydraulic engineer these machines with a focus on energy efficiency, continuous-duty performance, and precise compaction, ensuring that each bale meets the density requirements needed for smelting, recycling, and export operations.

Contact With Us

Feel free to write our team anytime

Overview

The working principle of an Aluminium and Steel Can Baler Machine is based on controlled hydraulic compression. Cans—whether loose, crushed, mixed, or sorted—are fed into the chamber manually or via conveyors. Once inside, the hydraulic ram exerts strong, uniform pressure to compress the material into a tightly packed bale. Depending on the model, the machine may offer single-action compression for small-scale operations or dual-action compression for achieving higher density in industrial environments. After compaction, the bale is tied using steel wire, plastic straps, or automated tying mechanisms to ensure stable form during handling and transport. This baling method ensures minimal air gaps within the bale, improving storage efficiency, increasing load capacity, and enhancing melting performance for recycling plants.

One of the biggest advantages of the Aluminium and Steel Can Baler Machine is its ability to handle lightweight but bulky metal waste that often occupies large space in warehouses and yards. Aluminum cans, due to their hollow structure, create unmanageable scrap volume unless efficiently compacted. By converting them into dense bales, industries can significantly reduce transportation frequency, lower logistics costs, and maximize truckload capacity. For recycling units, compact bales ensure faster furnace feeding, better melting efficiency, and higher throughput. Steel beverage cans and tin containers also compress effectively under the machine’s high-pressure mechanism, allowing mixed metal scrap to be handled without separate processes.

Durability and engineering strength are key characteristics of this machine. High-strength steel frames, wear-resistant compression plates, industrial-grade hydraulic cylinders, and precision-engineered components ensure the machine withstands long hours of operation in demanding industrial conditions. Machines manufactured by Jyoti Hydraulic are known for their consistent pressure output, smooth hydraulic performance, and long service life. These machines incorporate advanced PLC controls, pressure sensors, overload protection, and automated cycle sequencing to deliver safe, stable, and precise operation. Adjustable bale size options, variable compression settings, and customizable feeding mechanisms make the machine suitable for different scrap-handling needs and production scales.

Safety and operational convenience further enhance the machine’s performance. Equipped with emergency-stop switches, safety interlocks, guarded moving parts, and automatic shutdown systems, the baler ensures a secure environment for operators. The user-friendly control panel allows quick monitoring of compression cycles, hydraulic pressure, bale density, and running status. Maintenance tasks such as lubrication, hydraulic oil inspection, cleaning, and wear-part replacement are simplified through easily accessible service points. This reduces downtime and ensures continuous productivity, which is essential for high-volume recycling units.

From a business point of view, investing in an Aluminium and Steel Can Baler Machine results in long-term operational efficiency and profitability. Dense bales save considerable warehouse space, lower transportation expenses, and improve resale value of scrap. Recycling companies benefit from faster processing, increased furnace performance, and higher output of recovered metal. Environmental sustainability is another key benefit, as baling promotes responsible recycling, reduces landfill waste, and supports cleaner industrial operations.

Overall, the Aluminium and Steel Can Baler Machine is a highly efficient, durable, and cost-effective solution for industries dealing with large volumes of metal cans. It ensures higher productivity, consistent bale quality, and reduced operational effort—making it a strategic investment for modern scrap-processing and recycling environments.

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…