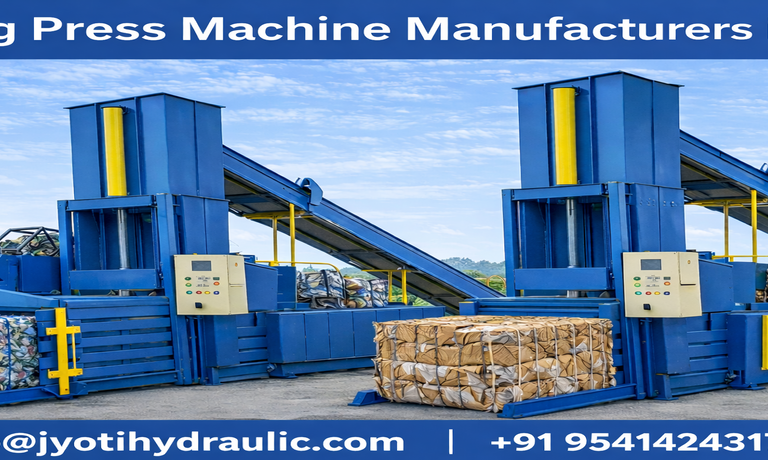

Continuous Paper Baling Machine

A Continuous Paper Baling Machine is a high-efficiency baling system designed to compact large volumes of paper waste into dense, uniform, and easy-to-handle bales without stopping the production cycle. This machine is widely used in recycling plants, corrugated box units, paper mills, printing houses, packaging industries, warehouses, and MRF facilities where paper waste is generated continuously throughout the day. Built for nonstop operation, the machine allows material feeding even during compression, ensuring maximum productivity and reduced manual intervention. Manufacturers like Jyoti Hydraulic design these machines with advanced hydraulic technology to support fast, automated, and consistent baling, helping industries streamline waste-processing operations and reduce overall handling costs. The continuous feeding and compression mechanism not only improves speed but also ensures that paper waste does not accumulate on the shop floor, maintaining a clean, safe, and highly efficient working environment.

Contact With Us

Feel free to write our team anytime

Overview

The working principle of a Continuous Paper Baling Machine revolves around a powerful horizontal hydraulic system that compresses paper scrap into compact, rectangular blocks. Material such as OCC, kraft paper, cardboard, newspaper, magazine waste, shredded paper, and packaging waste is fed into the baler via conveyors or manual hoppers. As the waste enters the compression chamber, the hydraulic ram applies strong, consistent pressure to compact the material. Once the bale reaches the preset size, the machine either signals the operator for tying or, in advanced models, automatically activates a wire-tying or strapping unit. This allows the baler to continue compressing new material while the finished bale is being tied and discharged, ensuring a continuous workflow without downtime. The entire operation is monitored through PLC-based controls, ensuring accuracy, safety, and uniform bale quality.

The machine’s robust construction is one of its key strengths. Heavy-duty steel frames, reinforced compression chambers, high-quality hydraulic cylinders, and wear-resistant plates ensure long-term durability and stable performance even in demanding industrial environments. Continuous balers designed by Jyoti Hydraulic incorporate precision-engineered components that minimize energy loss, reduce vibration, and provide consistent hydraulic pressure throughout extended working hours. Adjustable bale-size settings, pressure control systems, and customizable feeding mechanisms allow industries to achieve the exact bale density required for storage, resale, or export. Since paper waste varies in thickness, bulkiness, and moisture content, the machine is engineered to adapt to different grades of paper without compromising output quality.

Another significant advantage of a continuous baler is its ability to reduce labor dependency. Unlike manual or vertical balers that require frequent stopping for tying and bale removal, a continuous baling machine handles compression, tying, and ejection almost simultaneously. This reduces manpower requirements, eliminates operational delays, and ensures consistent bale output during peak production hours. The bales produced are dense, uniform, and easy to stack, resulting in lower transportation costs and optimized storage space. Exporters and recycling companies especially benefit from the machine’s ability to produce compact, high-density bales that meet international shipping standards.

Safety, automation, and maintenance efficiency further enhance the machine’s value. The system is equipped with multiple safety features such as emergency stop buttons, overload protection, automatic shutdown on system faults, and interlocked access doors that prevent accidental operation. The user-friendly control interface enables operators to monitor machine status, hydraulic pressure, bale length, and tie cycle in real time. Maintenance tasks like hydraulic oil checks, chamber cleaning, valve inspection, and lubrication are easy due to the machine’s service-friendly design. This ensures long operational life and minimum downtime, making it a reliable asset for continuous industrial use.

From a business perspective, investing in a Continuous Paper Baling Machine delivers long-term operational and financial benefits. It speeds up recycling processes, reduces waste-handling costs, increases bale uniformity, and improves overall efficiency. Dense bales occupy less space, enabling companies to transport more material in each load and maximize profitability. With rising demand for organized recycling and sustainable waste management, industries that use continuous balers gain a competitive edge through higher productivity and reduced environmental impact.

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…