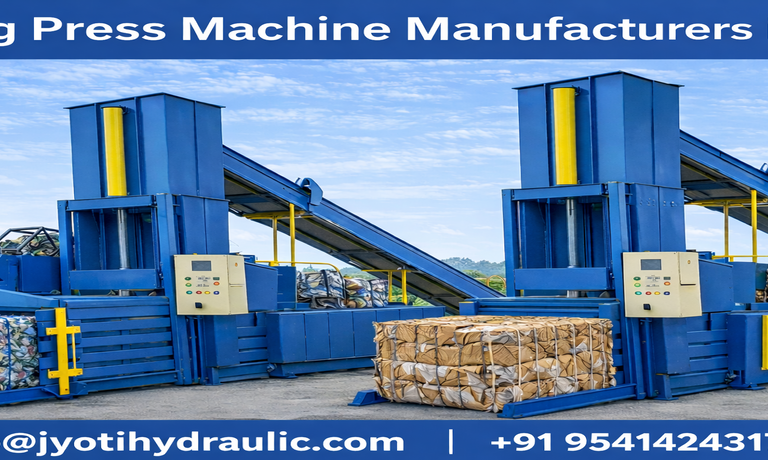

Horizontal Auto Tying Baling Press

A Horizontal Auto Tying Baling Press is a high-performance, fully automated baling solution engineered to manage large volumes of industrial scrap with maximum speed, consistency, and efficiency. This machine is specifically designed for high-output environments such as corrugated box factories, recycling plants, packaging units, paper mills, warehouses, and material recovery facilities where waste accumulates continuously throughout the day. Unlike traditional balers that require manual intervention for tying, this advanced system automatically binds each completed bale using steel wires or plastic straps, allowing the baling cycle to continue uninterrupted. The continuous feeding design ensures that new material enters the chamber while the previous bale is being tied and discharged, drastically increasing productivity. Manufacturers like Jyoti Hydraulic build these machines using cutting-edge hydraulic technology and smart automation to deliver exceptional output quality, uniform bale density, and long-term reliability under intensive working conditions.

Contact With Us

Feel free to write our team anytime

Overview

The operation of a Horizontal Auto Tying Baling Press is based on a high-pressure horizontal compression system supported by intelligent PLC-based controls. Waste material—whether cardboard, OCC, kraft paper, mixed paper scrap, PET bottles, soft plastics, LDPE films, textile rags, or lightweight metal cans—is fed through conveyors or pneumatic feeding systems. As the chamber fills, heavy-duty hydraulic rams move horizontally to compress the material into a compact block. Once the bale reaches preset length or density, the machine instantly activates its auto-tying mechanism. This automated process threads, tightens, and secures the bale within seconds, eliminating human error and ensuring consistent bale finishing. The machine then ejects the bale automatically, and the compression cycle resumes without delay, maintaining a smooth, continuous workflow essential for facilities processing several tons of waste daily.

One of the machine’s biggest advantages is its ability to reduce labor dependence while dramatically increasing processing efficiency. Since tying and bale removal occur automatically, operators only need to monitor feeding, machine status, and basic controls. This not only minimizes operational fatigue but also ensures uniform bale output even during extended shifts. The heavy-duty steel structure, reinforced side walls, and wear-resistant plates ensure long-term durability. The hydraulic cylinders, precision pumps, and control valves are engineered to deliver stable compression pressure, smooth ram movement, and low energy consumption. Continuous baling systems from Jyoti Hydraulic are built to withstand demanding industrial workloads, offering consistent performance round-the-clock without compromising safety or output quality.

The Horizontal Auto Tying Baling Press also stands out for producing high-density bales that reduce transportation and storage costs. Dense bales occupy significantly less space, allowing businesses to store more material in confined areas and ship larger quantities per truckload. Uniform bale dimensions help in systematic stacking, better container loading, and smoother downstream recycling processes. Exporters particularly value the uniformity and high density of these bales, as they meet international standards for recycling, shipping, and furnace feeding.

Operational safety and user-friendly design further enhance the value of this machine. Equipped with digital control panels, automated pressure monitoring, overload protection, emergency-stop systems, and safety interlocks, the baler ensures secure and stable operation for staff. The intelligent PLC displays real-time parameters such as bale length, pressure levels, tying cycles, and error notifications, allowing operators to make quick adjustments without halting production. The machine is also designed for easy maintenance: service points for lubrication, oil level checks, filter cleaning, and hydraulic system inspection are conveniently accessible, reducing downtime and increasing operational lifespan.

From a business perspective, investing in a Horizontal Auto Tying Baling Press offers significant long-term advantages. It reduces manpower costs, minimizes waste handling time, increases throughput, and improves bale resale value due to consistency in size and density. The machine supports sustainable waste management by converting loose, bulky scrap into compact, recyclable blocks that contribute to environmental conservation and responsible recycling. For industries aiming to enhance productivity, lower operational expenses, and maintain a cleaner working environment, this automated baling system is a highly efficient and future-ready solution.

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…