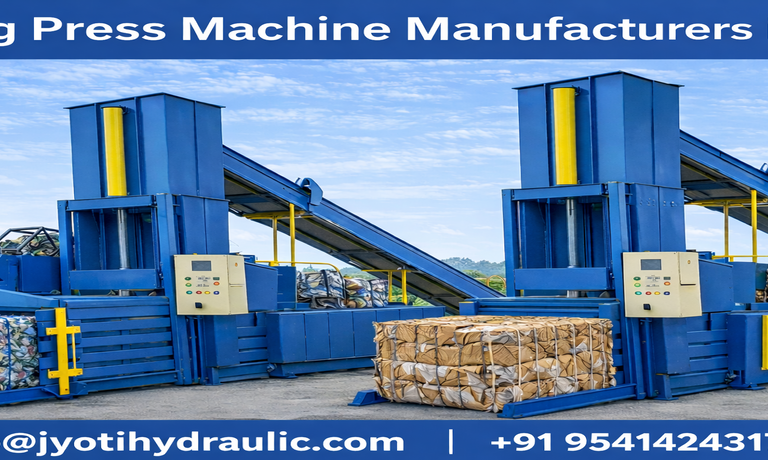

Vertical PET Bottles Baler Machine

A Vertical PET Bottles Baler Machine is a specialized hydraulic compaction system designed to compress loose and fluffy PET bottles into dense, stackable, and transport-friendly bales. With plastic waste increasing rapidly across manufacturing units, beverage plants, recycling centers, supermarkets, hotels, malls, and municipal waste facilities, the need for efficient PET bottle compaction has become essential. This vertical baler is engineered to deliver powerful downward compression while maintaining a compact footprint—making it ideal for small and medium-scale facilities that have limited floor space but require high-performance baling. Manufacturers like Jyoti Hydraulic design these balers to offer consistent bale density, low energy consumption, and long-term reliability, ensuring that industries can efficiently manage plastic waste while maintaining environmental compliance and reducing operational costs.

Contact With Us

Feel free to write our team anytime

Overview

The working mechanism of a Vertical PET Bottles Baler Machine is built around its vertical hydraulic ram, which applies high pressure to compress loose PET bottles inside the chamber. Operators load bottles manually into the chamber, often after removing caps or segregating materials for better bale quality. As the hydraulic ram descends, the bottles are flattened and compacted into a dense block. Once the pre-set compression level is reached, the operator ties the bale manually using plastic straps or PET-friendly binding material. The bale is then ejected—either manually or via a semi-automatic bale lifting system—and the machine is ready for the next cycle. This simple load–compress–tie operation provides high output efficiency for facilities handling moderate to large quantities of PET waste daily.

One of the most important advantages of a vertical PET baler is its ability to reduce plastic volume by up to 80–90%, dramatically improving storage and transportation efficiency. Loose PET bottles consume significant warehouse space due to their lightweight, hollow structure. By compacting them into uniform bales, businesses can drastically reduce storage requirements and transport more material in fewer trips. This directly lowers logistics costs and increases profitability for recycling businesses. Dense bales are also preferred by recycling plants and plastic processors because they feed smoothly into shredders, washing lines, and reprocessing equipment, improving the overall efficiency of the recycling chain.

Durability and engineering precision are defining characteristics of a vertical PET baler. Machines produced by Jyoti Hydraulic are built with heavy-duty steel frames, reinforced chamber walls, industrial-grade hydraulic cylinders, and specialized wear-resistant plates to withstand continuous operation in dusty and plastic-rich environments. The hydraulic system is designed to maintain stable pressure output while consuming minimal electricity, making the machine energy-efficient and economical. Adjustable bale-height settings, variable compression controls, and customizable chamber sizes allow industries to produce bales that meet market standards and export specifications.

Safety and user-friendly operation further elevate the machine’s value. The control panel includes easy-to-use switches or buttons to operate compression cycles, monitor pressure, and manage bale ejection. Safety features such as door interlocks, overload protection, emergency-stop systems, and guarded moving components ensure secure operation for users. The baler’s structural design provides clear visibility during the tying process and safe access for loading PET bottles, minimizing operator fatigue and improving workflow efficiency. Even new operators can learn to use the machine quickly, making it ideal for both small-scale and large-scale recycling operations.

Maintenance requirements for a vertical PET bottle baler are minimal due to its simple mechanical design and high-quality hydraulic components. Routine tasks such as checking oil levels, lubricating moving parts, cleaning the chamber, and inspecting straps or guiding mechanisms are quick and straightforward. The machine’s reliability and low servicing needs ensure long operational life and reduced downtime, providing better ROI for businesses.

From a business standpoint, investing in a Vertical PET Bottles Baler Machine delivers long-term benefits. It helps industries organize waste, reduce clutter, improve hygiene, increase recycling revenue, and comply with environmental policies. Compact bales ensure better resale value in the recycling market, while reduced waste volume supports cleaner and safer working environments. For companies aiming to improve sustainability and operational efficiency, a vertical PET baler is a smart and cost-effective solution.

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…