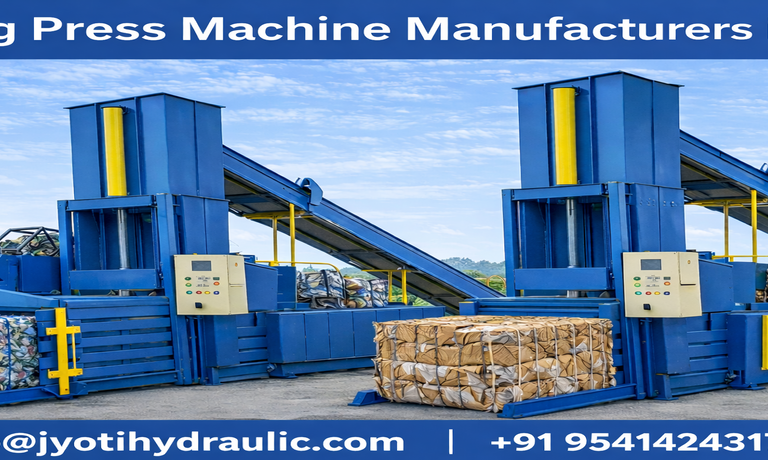

Vertical Scrap B Baler Machine

A Vertical Scrap Baler Machine is a compact, powerful, and highly efficient waste-compaction solution designed for industries that need space-saving, reliable, and cost-effective baling performance. Built with a vertically oriented compression system, this machine is ideal for small, medium, and even large-scale operations that handle varied types of scrap materials such as cardboard, paper, PET bottles, HDPE containers, aluminum cans, textile waste, foam, plastic films, fabric offcuts, and light-metal scrap. Its vertical design allows it to fit comfortably into limited floor spaces while still delivering high compression force, making it a preferred choice for retail stores, warehouses, logistic centers, packaging units, recycling facilities, manufacturing plants, supermarkets, and waste-collection businesses. The machine operates on a simple feed-and-compress mechanism where scrap is loaded into the chamber, compressed by a powerful hydraulic ram, and tied manually or semi-automatically to form compact, transport-friendly bales. This helps industries significantly reduce waste volume, cut down transportation expenses, maintain cleaner workspaces, and streamline their waste-management processes.

Contact With Us

Feel free to write our team anytime

Overview

One of the biggest advantages of a vertical baler is its versatility and ease of operation. Unlike large horizontal balers that require conveyors or continuous feeding systems, a vertical scrap baler allows operators to feed materials manually and run compaction cycles with straightforward controls. This makes it highly suitable for facilities with moderate waste output or those seeking a low-maintenance, energy-efficient baling solution. The machine’s hydraulic system delivers strong, stable compression force to create dense bales with consistent shape and weight. Depending on the model and capacity, vertical balers can produce bales in a range of sizes—from small, easy-to-lift blocks to large, heavy bales suitable for recycling units and resale. Many industries choose vertical balers as their first step toward structured waste management because of their low investment cost, simple mechanism, and long operational life.

A Vertical Scrap Baler Machine is built with a heavy-duty steel frame, wear-resistant plates, and industrial-grade hydraulic cylinders to withstand daily usage in tough working environments. The compression chamber is designed to endure high pressure without deformation, ensuring durability and stable performance throughout years of operation. Many models include features such as adjustable bale height, high-strength tying channels, pressure gauges, automatic door locking, and customizable bale weights. Safety is a key consideration in vertical baler design. Most machines come equipped with safety interlocks, emergency stop buttons, overload protection, and guarded moving components to ensure operators remain secure during loading, compression, and bale removal. With minimal training, operators can run the machine efficiently, making it an ideal addition for companies looking to improve waste-handling productivity without complex installation or technical challenges.

The machine’s maintenance requirements are relatively low compared to horizontal or continuous balers. Routine tasks such as checking hydraulic oil levels, lubricating moving parts, cleaning the chamber, and inspecting electrical components are simple and quick to perform. The hydraulic system, motors, and seals are designed for long service life, reducing downtime and minimizing repair costs. Many vertical balers also include easy-access panels to support hassle-free servicing. Because the machine consumes less electricity and requires fewer operational resources, it is an economical solution for businesses prioritizing sustainable and cost-effective waste management. Its compact footprint, combined with powerful compaction capability, makes it suitable for both standalone installations and integration into existing waste-handling systems.

From a business perspective, investing in a Vertical Scrap Baler Machine delivers numerous advantages. It significantly reduces the volume of waste materials—sometimes by up to 80%—which directly lowers storage needs and transportation frequency. Compact bales are easier to handle, stack, and sell to recycling vendors, ensuring better material value and cleaner work environments. The machine helps industries maintain compliance with waste-management regulations while promoting eco-friendly recycling practices and sustainable operational methods. Whether used in commercial facilities, industrial plants, or recycling centers, a vertical scrap baler improves workflow efficiency, enhances waste segregation, and supports long-term cost savings.

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…