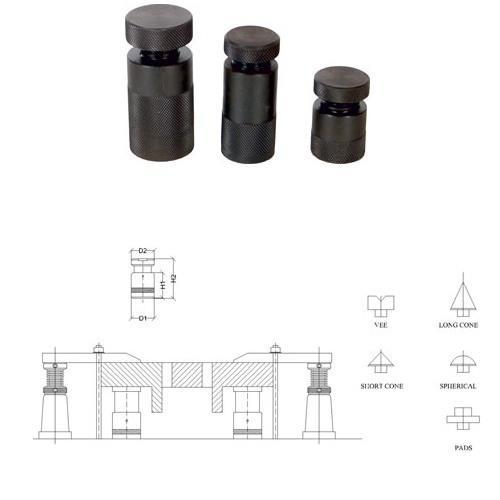

Leveling Pad Manufacturers in India

Jyoti Hydraulic stands among the leading Leveling Pad Manufacturers in India, delivering advanced solutions designed for stability and heavy-duty performance in diverse industrial environments. Our leveling pads are engineered to provide superior support, vibration absorption, and reliable load-bearing capacity—ensuring that your machinery and equipment operate with maximum efficiency and minimal downtime.

Why Choose Jyoti Hydraulic Leveling Pads?

- Heavy-Duty Engineering: Each leveling pad is crafted using premium-grade materials to withstand heavy loads and continuous operation in demanding industrial settings.

- Corrosion-Resistant Finish: Our leveling pads are protected with a corrosion-resistant surface, making them ideal for harsh manufacturing floors and outdoor installations.

- Easy Installation: Designed for hassle-free mounting and adjustment, Jyoti Hydraulic’s leveling pads can be installed without specialized tools or extensive downtime.

- Versatile Applications: Our products are suitable for CNC machines, compressors, conveyors, packaging equipment, and all types of industrial machinery.

- Precision Leveling: Achieve perfect alignment for your machines, reducing vibrations and enhancing equipment lifespan.

Key Features of Jyoti Hydraulic Leveling Pads

- High Load Capacity: Supports a wide range of equipment sizes and weights.

- Adjustable Height: Effortless height adjustment for precise leveling on uneven surfaces.

- Vibration Isolation: Effectively dampens vibrations, safeguarding sensitive machinery components.

- Non-Slip Base: Secure grip on various floor types to prevent movement or slippage.

- Maintenance-Free: Robust build quality requires minimal maintenance even in heavy-duty operations.

Applications of Leveling Pads

Jyoti Hydraulic’s leveling pads are trusted across multiple industries, including:

- Automotive

- Food Processing

- Textile Mills

- Packaging Plants

- Pharmaceuticals

- Heavy Engineering

Whether you’re setting up new equipment or optimizing existing setups, our leveling pads provide the foundation for seamless operations.

Custom Solutions Available

As an innovative Leveling Pad Manufacturer in India, Jyoti Hydraulic understands that every industry has unique requirements. We offer customized leveling pads tailored to specific sizes, load capacities, and environmental challenges. Our engineering team collaborates closely with clients to deliver made-to-order solutions that exceed expectations.

Quality Assurance & Standards

Jyoti Hydraulic follows stringent quality control at every stage of production. Each leveling pad is thoroughly inspected and tested for:

- Dimensional accuracy

- Load-bearing capacity

- Vibration resistance

- Surface finish

We comply with global standards to ensure reliability and performance in every unit delivered.

Why Jyoti Hydraulic is the First Choice for Leveling Pads in India

- Trusted Brand Reputation: Years of expertise as a top hydraulic and mechanical solution provider.

- Nationwide Supply Network: Quick, on-time delivery across India.

- Dedicated Technical Support: Responsive after-sales service and technical assistance.

- Competitive Pricing: Affordable rates without compromising on quality.

Frequently Asked Questions (FAQs)

Q1. What is a leveling pad and why is it important?

A leveling pad is a mechanical support used to stabilize and align industrial machines, reducing vibrations and ensuring accurate operation.

Q2. Can Jyoti Hydraulic provide custom-designed leveling pads?

Yes, Jyoti Hydraulic specializes in custom solutions based on your equipment specifications and operational requirements.

Q3. Are your leveling pads suitable for heavy machinery?

Absolutely. Our leveling pads are engineered to handle heavy loads and continuous industrial use.

Q4. How do I choose the right leveling pad for my machine?

Contact Jyoti Hydraulic’s expert team with your machine details, and we will recommend the most suitable leveling pad for your application.

Q5. What materials are used in your leveling pads?

We use premium-grade metals and composite materials to ensure maximum durability, corrosion resistance, and load-bearing capacity.