Hydraulic Cylinder Manufacturer in India

A hydraulic cylinder is a mechanical device designed to produce unidirectional force through a unidirectional stroke. It converts hydraulic energy into linear motion and is widely used in industrial machinery, construction equipment, and engineering vehicles. The system operates using pressurized hydraulic fluid and consists of a barrel, piston, and piston rod, ensuring smooth, efficient performance under heavy loads.

Jyoti Hydraulic is one of the leading hydraulic cylinder manufacturers in India, offering high-quality and cost-effective cylinders for industrial, mobile, and heavy-duty applications.

📞 Contact: +91 9541424317

📧 Email: jyotihydraulic@gmail.com

Get Your Quote Instantly

Our Products

Overview

Round Flange Welded Hydraulic Cylinder

These cylinders are commonly used in modern industries for their compact design and strong welded construction. They offer reliable performance, are cost-effective, and ensure safe operation under high pressure. Ideal for material handling, earth-moving, and industrial presses, Jyoti Hydraulic provides different flange welded designs customized as per client needs.

Block Hydraulic Cylinder

Block-type hydraulic cylinders are designed for heavy-load applications where compactness and durability are essential. They are easy to install and maintain, making them suitable for clamping systems, molding machines, and lifting mechanisms. Jyoti Hydraulic ensures precision design and high performance at competitive prices.

Tie Rod Hydraulic Cylinder

The tie-rod hydraulic cylinder is widely used in machine tools and automotive equipment. Known for its service-friendly modular construction, it’s both compact and flexible for various installation requirements. Jyoti Hydraulic manufactures standard and custom tie-rod cylinders, ensuring excellent pressure capacity and long service life.

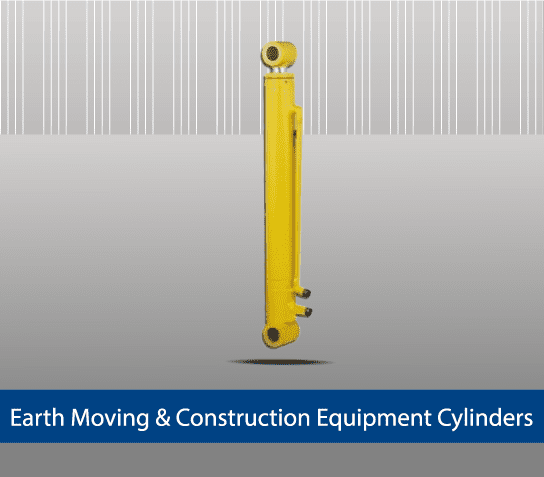

Mobile Hydraulic Cylinder

Used in mobile and outdoor machinery like tippers, loaders, and tractors, the mobile hydraulic cylinder is designed for rugged environments. With its corrosion-resistant finish and strong structure, it offers smooth motion and durability in harsh operating conditions.

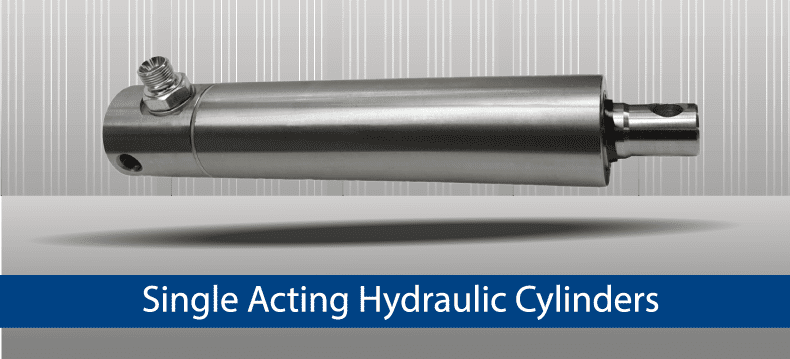

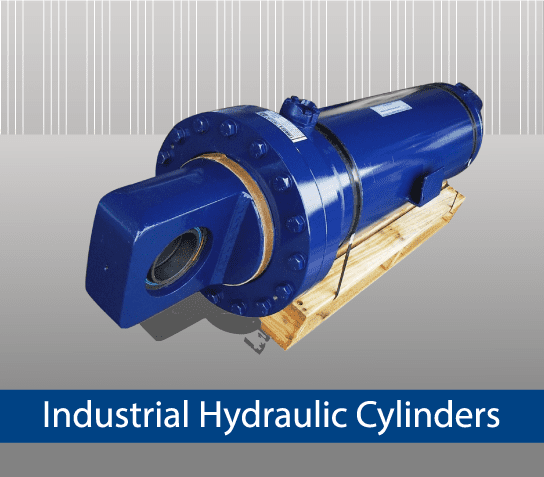

Industrial & High-Pressure Hydraulic Cylinders

Jyoti Hydraulic manufactures industrial and high-pressure hydraulic cylinders to meet modern engineering demands. Built using high-tensile materials and advanced machining, these cylinders are tested for performance, leak resistance, and durability. They are perfect for presses, cranes, steel plants, and heavy machinery applications.

Key Features:

- Long service life and minimal maintenance

- Compact and robust design

- Safe, reliable, and energy-efficient operation

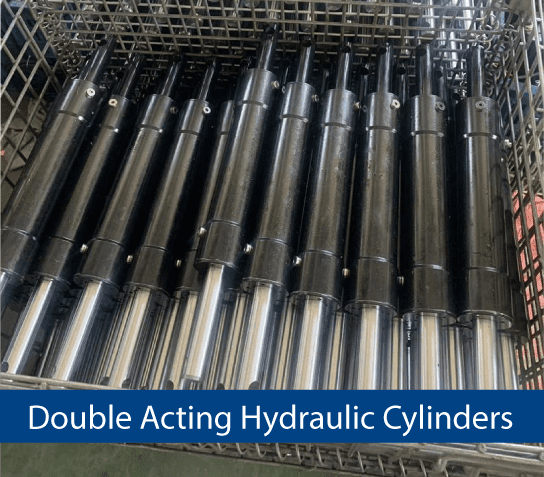

Double Acting Hydraulic Cylinder

A double-acting cylinder operates in both forward and reverse directions. It has two ports for hydraulic oil and provides controlled motion in lifting, pushing, and pressing operations. Jyoti Hydraulic designs these cylinders with precision to ensure stable, efficient, and long-lasting performance.

Why Choose Jyoti Hydraulic

- High-quality, tested products

- Custom designs for specific requirements

- Competitive pricing and timely delivery

- Experienced technical support team

- Pan-India supply and service

If you are looking for a reliable Hydraulic Cylinder Manufacturer in India, choose Jyoti Hydraulic for trusted quality, performance, and value.

📞 Call / WhatsApp: +91 9541424317

📧 Email: jyotihydraulic@gmail.com

Blogs

-

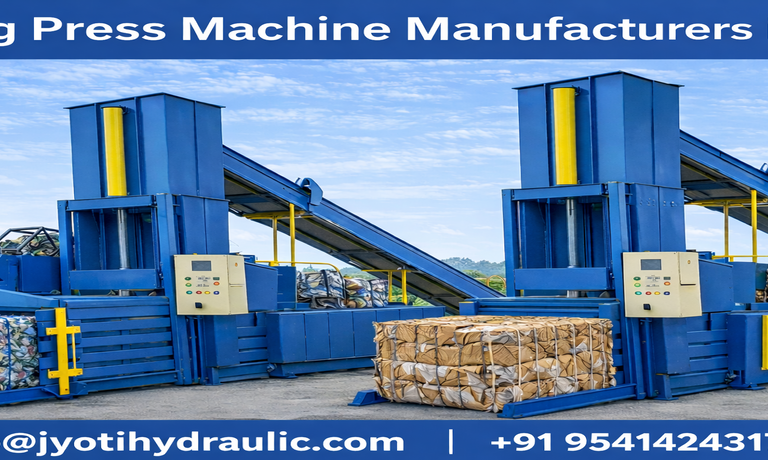

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…