Telescopic Cylinder Manufacturers in India

Telescopic Cylinder Manufacturers in India play a critical role in supplying compact yet high-stroke hydraulic solutions for vehicles and industrial equipment where space efficiency and lifting power are essential. Telescopic cylinders are specially engineered multi-stage hydraulic cylinders designed to deliver long extension lengths while maintaining a short retracted size, making them ideal for tipper trucks, dumpers, trailers, agricultural machinery, and heavy-duty industrial applications.

Get Your Quote Instantly

Overview

What Is a Telescopic Hydraulic Cylinder

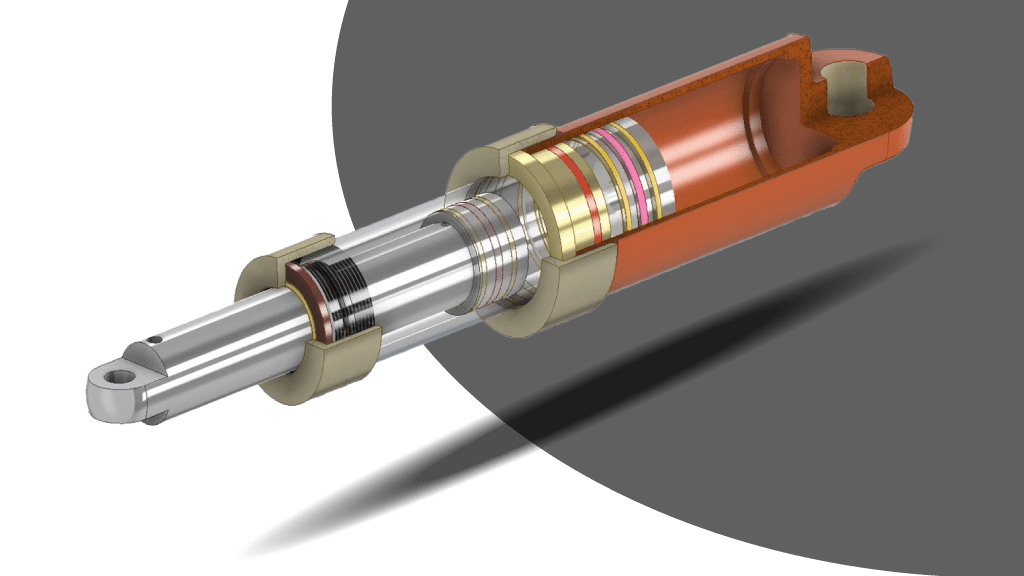

A telescopic hydraulic cylinder consists of multiple nested stages that extend sequentially under hydraulic pressure. Each stage is precisely machined to ensure smooth movement, load stability, and long service life. Compared to conventional hydraulic cylinders, telescopic cylinders offer superior space utilization, higher lifting heights, and flexible design options for challenging applications.

In the Indian manufacturing and transport sector, telescopic cylinders are widely preferred due to their adaptability, rugged construction, and ability to operate reliably under heavy loads and harsh working conditions.

Types of Telescopic Cylinders Available in India

Telescopic cylinders are manufactured in different configurations to suit specific operational needs.

Single acting telescopic cylinders use hydraulic pressure for extension, while retraction occurs through gravity or load force. These are commonly used in tipper trucks and dump trailers.

Double acting telescopic cylinders use hydraulic pressure for both extension and retraction, providing greater control, precision, and safety. They are ideal for specialized industrial and mobile equipment.

Multi-stage telescopic cylinders are available in two-stage, three-stage, four-stage, and higher configurations, depending on stroke length and lifting requirements.

Key Applications of Telescopic Cylinders

Telescopic cylinders are extensively used across multiple industries in India.

In tipper trucks and dumpers, they enable efficient material unloading with stable lifting performance.

In agricultural trailers, they assist in lifting and tilting operations with minimal space usage.

In construction and mining equipment, they handle heavy loads under continuous duty cycles.

In industrial machinery, they support vertical lifting, positioning, and material handling operations.

In waste management vehicles, they ensure smooth and controlled tipping actions.

Design and Engineering Standards

High-quality telescopic cylinders manufactured in India follow strict engineering and quality control standards. Precision honed tubes, hard chrome-plated piston rods, and high-strength alloy steel components ensure durability and performance consistency.

Advanced sealing systems are used to minimize oil leakage, prevent contamination, and extend maintenance intervals. Surface finishing and dimensional accuracy play a crucial role in reducing friction, wear, and energy loss during operation.

Every telescopic cylinder is designed to operate efficiently at specified working pressures and load capacities, ensuring safety and reliability throughout its service life.

Factors That Define Telescopic Cylinder Performance

The performance of a telescopic cylinder depends on several technical parameters.

Load capacity determines the maximum weight the cylinder can safely lift.

Stroke length defines the extension range required for the application.

Operating pressure affects lifting force and system efficiency.

Number of stages influences compactness and extension capability.

Mounting style ensures proper installation and load alignment.

A well-designed telescopic cylinder balances all these factors to deliver optimal performance without excessive stress on the hydraulic system.

Custom Telescopic Cylinder Manufacturing in India

Indian manufacturers offer customized telescopic cylinders tailored to specific application requirements. Customization options include stroke length, bore size, mounting configuration, operating pressure, and sealing arrangements.

Customized manufacturing ensures compatibility with existing hydraulic systems, improved efficiency, and longer service life. It also helps reduce downtime and operational issues caused by improper cylinder selection.

Quality Testing and Inspection

Reliable telescopic cylinder manufacturers in India conduct multiple quality checks before dispatch. These include dimensional inspection, surface finish evaluation, pressure testing, and leakage testing.

Hydrostatic pressure testing ensures the cylinder can withstand operating and peak pressures safely. Functional testing verifies smooth extension and retraction of all stages. These quality measures are essential for maintaining safety standards and customer confidence.

Advantages of Choosing Indian Telescopic Cylinder Manufacturers

Indian manufacturers offer a strong balance of quality, cost efficiency, and technical expertise. Locally manufactured telescopic cylinders provide faster delivery timelines, easier customization, and readily available service support.

Compared to imported alternatives, Indian-made telescopic cylinders reduce total ownership cost by minimizing downtime, spare part delays, and maintenance complexity. Continuous advancements in manufacturing technology have further improved consistency and durability.

Maintenance and Service Life

Proper installation, clean hydraulic oil, and periodic inspection significantly enhance the life of telescopic cylinders. Regular seal checks, rod surface inspection, and adherence to recommended operating pressures help prevent premature wear.

High-quality telescopic cylinders are designed for long service intervals and stable performance even under repetitive heavy-duty operations.

Why Choose the Right Manufacturer

Selecting the right telescopic cylinder manufacturer in India is essential for long-term operational success. A reliable manufacturer provides technical consultation, correct product selection, transparent specifications, and after-sales support.

Manufacturer-direct sourcing ensures better pricing, consistent quality, and application-specific engineering support, which is especially important for OEMs and fleet operators.

Manufacturer Support and Technical Guidance

Professional manufacturers assist customers with application analysis, load calculation, and system compatibility checks. This engineering-driven approach ensures the telescopic cylinder performs efficiently throughout its lifecycle.

Strong technical support reduces installation errors, improves system safety, and maximizes productivity.

Conclusion

Telescopic Cylinder Manufacturers in India continue to play a vital role in supporting infrastructure growth, transportation, agriculture, and industrial development. Choosing the right telescopic hydraulic cylinder involves understanding application requirements, quality standards, and long-term value rather than focusing only on initial cost.

For reliable performance, customized solutions, and manufacturer-direct support, Jyoti Hydraulic offers engineered telescopic cylinders designed to meet demanding operational needs with consistency, safety, and durability.

📧 Email: jyotihydraulic@gmail.com | info@jyotihydraulic.com

📞 Contact: +91 9541424317

Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…