Hydraulic Power Pack Manufacturer in India

Hydraulic Power Pack Manufacturer in India is a highly searched term by industries that rely on efficient force transmission, precision control, and long-term operational reliability. A hydraulic power pack is not just a supporting unit; it is the heart of any hydraulic system, responsible for generating pressure, controlling flow, and ensuring smooth machine performance. As a professional Hydraulic Power Pack Manufacturer in India, Jyoti Hydraulic designs and manufactures robust, energy-efficient, and application-specific hydraulic power packs for a wide range of industrial and mobile applications.

Our Products

Overview

Understanding Hydraulic Power Packs in Industrial Systems

A hydraulic power pack is a self-contained assembly that converts electrical or mechanical energy into hydraulic energy. This energy is then transmitted through pressurized hydraulic oil to perform mechanical work such as lifting, pressing, pushing, pulling, or rotating loads.

Hydraulic power packs are preferred in industrial environments because they can generate extremely high force from compact systems while maintaining precise control. Unlike pneumatic or mechanical systems, hydraulic power packs provide smooth motion, consistent torque, and superior load-holding capability.

Why Hydraulic Power Pack Design Matters

The performance of a hydraulic system depends heavily on how well the power pack is engineered. Poorly designed power packs can lead to pressure fluctuations, overheating, excessive power consumption, oil leakage, and frequent breakdowns.

A reliable hydraulic power pack manufacturer in India focuses on:

Accurate pressure and flow calculations

Correct pump and motor selection

Heat dissipation and oil cooling

Contamination control and filtration

System safety and overload protection

Jyoti Hydraulic follows an application-first engineering approach to ensure each power pack delivers stable performance under real operating conditions.

Types of Hydraulic Power Packs Manufactured in India

As an experienced hydraulic power pack manufacturer in India, Jyoti Hydraulic manufactures multiple configurations to suit different industries and operating environments.

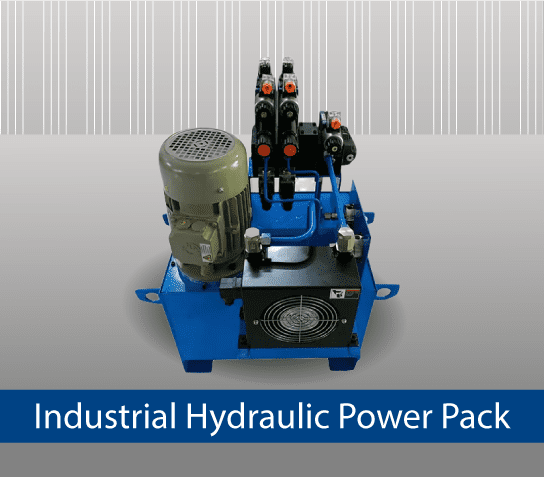

AC Hydraulic Power Packs

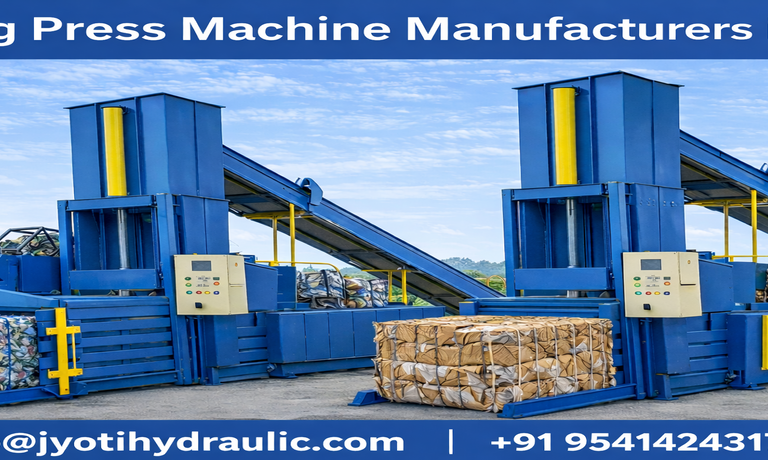

AC hydraulic power packs are widely used in industrial plants where continuous power supply is available. These power packs are suitable for heavy-duty machines such as hydraulic presses, baling machines, production equipment, and automation systems. They offer long service life and consistent output for continuous operations.

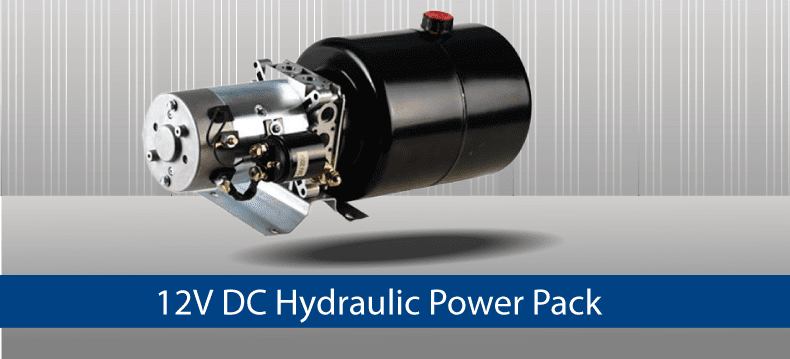

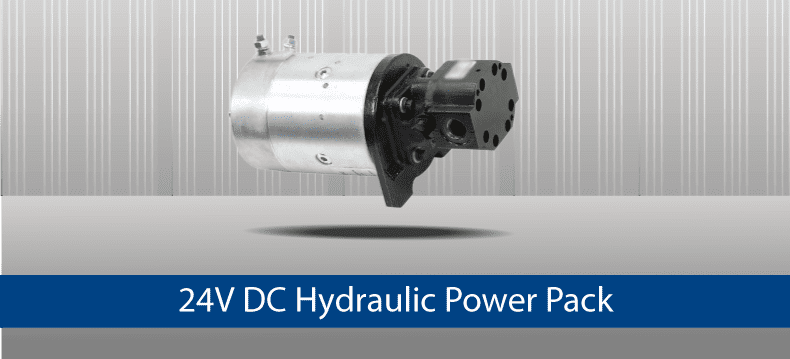

DC Hydraulic Power Packs

DC hydraulic power packs are powered by batteries and commonly used in mobile and remote applications. These include tailgate lifters, scissor lifts, dumpers, pickup trucks, and emergency equipment. DC power packs are available in 12V, 24V, 48V, and 60V configurations depending on load requirements.

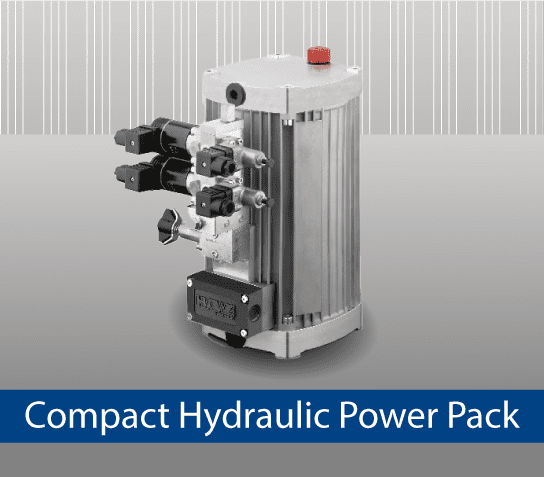

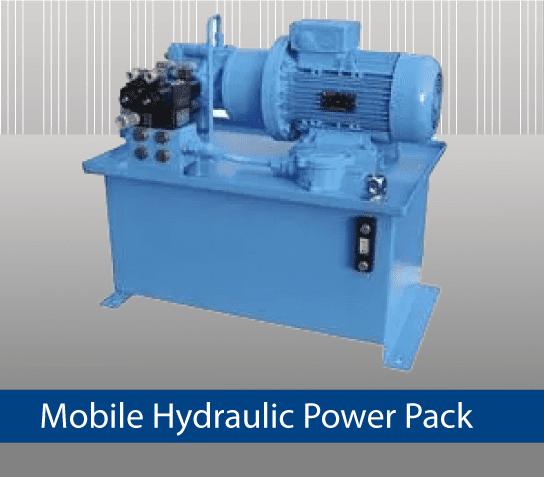

Compact and Mini Hydraulic Power Packs

Mini hydraulic power packs are designed for space-constrained applications where compact size and efficient performance are critical. These power packs are commonly used in small machines, lifting platforms, and special-purpose equipment.

Customized Hydraulic Power Packs

Customized hydraulic power packs are engineered to match exact operational requirements. Parameters such as pressure rating, oil flow, duty cycle, voltage, mounting orientation, and environmental conditions are carefully analyzed. Jyoti Hydraulic specializes in custom-built hydraulic power packs for OEMs and industrial users.

Core Components of a Hydraulic Power Pack

A well-designed hydraulic power pack consists of several critical components that work together seamlessly.

Electric Motor or Prime Mover

The motor provides the mechanical energy required to drive the hydraulic pump. Motor selection depends on voltage availability, load conditions, and operating cycle.

Hydraulic Pump

The pump converts mechanical energy into hydraulic pressure. Gear pumps are commonly used for standard applications, while vane and piston pumps are selected for higher efficiency and pressure stability.

Oil Reservoir

The reservoir stores hydraulic oil, allows air separation, dissipates heat, and provides space for contaminants to settle.

Valves and Manifolds

Directional, pressure, and flow control valves regulate the movement, speed, and safety of hydraulic systems.

Filtration and Cooling System

Filters remove contaminants from hydraulic oil, while cooling systems prevent overheating and maintain oil viscosity.

Industrial Applications of Hydraulic Power Packs

A dependable hydraulic power pack manufacturer in India must cater to multiple industries. Hydraulic power packs are widely used in:

Baling press machines for PET bottles, scrap metal, cartons, and waste paper

Hydraulic presses and forming machines

Material handling and lifting equipment

Construction and infrastructure machinery

Automobile service and workshop equipment

Agricultural and farm machinery

Mobile hydraulic systems and transport equipment

Jyoti Hydraulic manufactures power packs that perform efficiently in both stationary and mobile applications.

Benefits of High-Quality Hydraulic Power Packs

Investing in a professionally manufactured hydraulic power pack delivers measurable advantages:

Higher machine efficiency and output

Reduced power loss and energy consumption

Lower maintenance and repair costs

Improved operational safety

Consistent performance under load

Extended service life of hydraulic components

These benefits directly impact productivity and operational cost savings.

Manufacturing Process and Quality Control

Jyoti Hydraulic follows a structured manufacturing process to ensure reliability and performance:

Requirement analysis and system design

Precision machining and component sourcing

Assembly using quality-tested parts

Pressure, leakage, and performance testing

Final inspection and validation

Each hydraulic power pack is tested under working conditions before dispatch, ensuring compliance with industrial standards.

Customization and Engineering Support

Customization is a key requirement for many industries. As a leading hydraulic power pack manufacturer in India, Jyoti Hydraulic offers:

Application-specific pressure and flow configurations

AC and DC voltage options

Compact and space-saving designs

Special oil compatibility for extreme temperatures

Integration with PLC and automation systems

Engineering support ensures customers receive a solution tailored to their operational needs.

Why Choose Jyoti Hydraulic as Your Hydraulic Power Pack Manufacturer in India

Jyoti Hydraulic is trusted by industries across India due to:

Proven manufacturing expertise

Strong focus on engineering quality

Customized hydraulic solutions

Reliable technical and after-sales support

Commitment to performance and durability

Our goal is to deliver hydraulic power packs that perform efficiently throughout their operational life.

Contact Hydraulic Power Pack Manufacturer in India

For reliable, efficient, and customized hydraulic power pack solutions, connect with Jyoti Hydraulic.

Email: jyotihydraulic@gmail.com | info@jyotihydraulic.com

Phone: +91 9541424317

Frequently Asked Questions (FAQs)

What does a hydraulic power pack do?

A hydraulic power pack generates hydraulic pressure and flow required to operate hydraulic machines such as presses, lifts, and baling machines.

How do I choose the right hydraulic power pack?

Selection depends on pressure requirement, oil flow rate, duty cycle, power supply, and application type. Consulting an experienced hydraulic power pack manufacturer in India helps ensure the correct choice.

What is the difference between AC and DC hydraulic power packs?

AC power packs are used in stationary industrial applications, while DC power packs are battery-operated and ideal for mobile equipment.

Can hydraulic power packs be customized?

Yes, hydraulic power packs can be fully customized based on pressure, flow, voltage, size, and application requirements.

How often does a hydraulic power pack require maintenance?

Routine oil inspection, filter replacement, and system checks are recommended to ensure long-term performance and reliability.

Which industries use hydraulic power packs?

Industries such as manufacturing, recycling, construction, agriculture, and transportation widely use hydraulic power packs.

Contact With Us

Feel free to write our team anytime

Our Blogs

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…

-

Hydraulic Baling Machine Price Guide by Jyoti Hydraulic

Read MoreJyoti Hydraulic brings industry-backed expertise to businesses looking for reliable…

-

Double Action Hydraulic Baling Press Machine Price in India

Read MoreJyoti Hydraulic is one of the leading names when it…