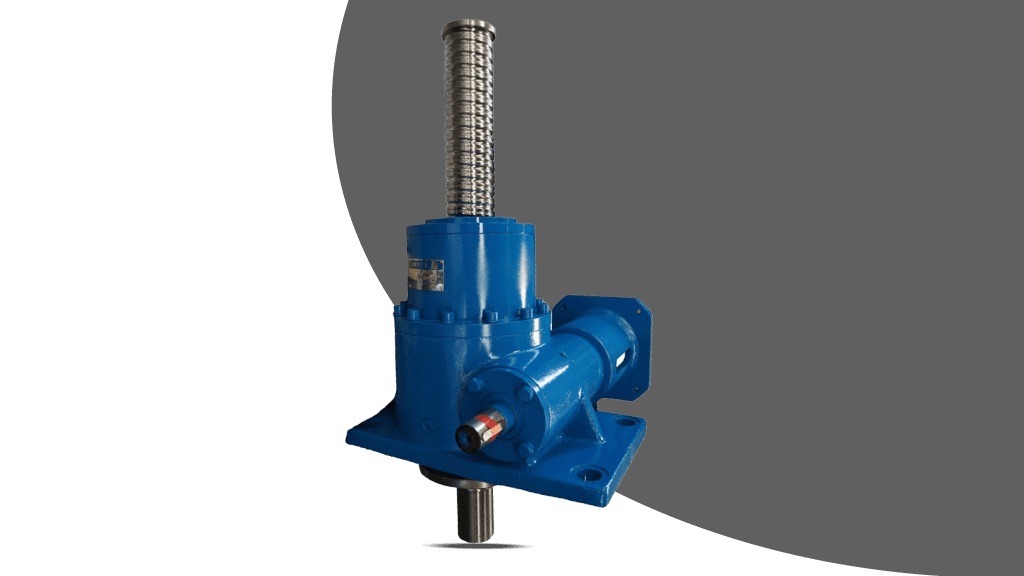

Classic Worm Gear Screw Jacks Manufacturer in India

A classic worm gear screw jack is a heavy-duty mechanical lifting system designed to provide linear motion for precise load handling, lifting, lowering, and positioning. Using a worm gear mechanism, these screw jacks offer high load capacity, self-locking capability, and smooth operation, making them ideal for industrial automation, material handling, construction, and heavy machinery applications. Jyoti Hydraulic, a leading classic worm gear screw jacks manufacturer, specializes in custom-engineered, durable, and high-efficiency screw jacks that ensure maximum performance and reliability in various industrial sectors.

As an ISO-certified classic worm gear screw jacks manufacturer in India, Jyoti Hydraulic produces precision-built lifting solutions using premium-grade materials, advanced worm gear systems, and high-strength components. Our classic screw jacks are available in multiple load capacities, gear ratios, and stroke lengths, ensuring customized solutions for different load-handling requirements. With manual and motorized operation options, our worm gear screw jacks deliver efficient, controlled, and long-lasting performance in industrial environments.

Key Features

Heavy-Duty Worm Gear Drive – Designed with a high-precision worm gear system, ensuring smooth torque transfer, controlled lifting, and reliable load handling.

Self-Locking Mechanism – Offers enhanced safety and stability by preventing back-driving of the load, ensuring secure positioning even without continuous power supply.

Customizable Load Capacities & Stroke Lengths – Available in various weight-handling capacities and stroke sizes, allowing flexible integration into industrial lifting and positioning systems.

Corrosion-Resistant & Durable Construction – Manufactured with high-strength steel and coated with corrosion-resistant finishes, ensuring long service life and resistance to wear and tear in harsh environments.

Manual & Motorized Operation – Suitable for hand-operated systems and electric motor integration, offering versatile lifting solutions for different industrial applications.

High Load-Carrying Capacity – Capable of handling extreme loads with precision and efficiency, making it ideal for manufacturing units, assembly lines, construction sites, and automation systems.

Versatile Industrial Applications – Widely used in machinery lifting, heavy-load positioning, industrial presses, stage and theater rigging, material handling equipment, and automated production systems, ensuring reliable and efficient motion control.