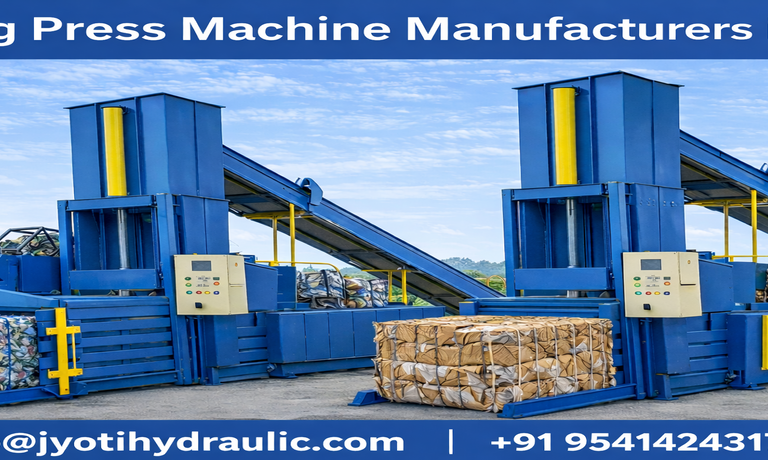

Continuous Paper Baling Machine Auto Tying

A Continuous Paper Baling Machine Auto Tying is an advanced, high-efficiency baling solution designed for industries that require nonstop processing of paper waste with minimal manual intervention. This machine is engineered to handle large volumes of paper scrap—such as OCC, newspaper, kraft paper, printing waste, packaging waste, and shredded paper—while maintaining uniform bale size, consistent density, and superior output quality. Its fully automated tying system eliminates manual strapping, reduces operational labor, and enhances production speed, making it an ideal choice for recycling plants, paper mills, packaging units, corrugation industries, warehouses, and material recovery facilities. The machine operates on a continuous feeding concept, allowing paper waste to be fed without pausing the compression cycle. As a result, industries achieve higher throughput, reduced downtime, improved space management, and lower operational costs. With growing demand for fast recycling processes and sustainability, this machine has become a core asset for companies aiming to optimize waste handling and increase profitability.

Contact With Us

Feel free to write our team anytime

Overview

A continuous auto-tying baling machine works on a streamlined hydraulic compression system supported by advanced PLC controls that ensure precise, repeatable, and safe operation. The hydraulic cylinder applies uniform pressure to compress paper scrap into dense, compact bales that are easy to transport, store, and recycle. Once the bale reaches the pre-set size or weight, the automatic tying mechanism activates to wrap the bale with strong wire or plastic straps. This step is executed within seconds, enabling uninterrupted workflow and ensuring each bale maintains structural integrity even during long-distance transportation. The integration of sensors, limit switches, and safety interlocks enhances accuracy and prevents machine overload, overheating, or mechanical failure. The auto-tying system also minimizes human error, ensures neat finishing, and increases operational efficiency by up to 40% compared to manual tying machines.

One of the major benefits of this machine is its ability to handle continuous feeding throughout the day. Industries with high daily waste output, such as corrugation plants or printing presses, often struggle with manual baling because it disrupts production flow. A continuous paper baler solves this by allowing waste to be fed through conveyor belts, loaders, or air conveying systems directly into the machine. This not only saves manpower but also maintains a clutter-free working environment. The compaction ratio achieved by the machine significantly reduces transportation costs, as more material can be loaded per trip. Its robust hydraulic power pack ensures a strong, stable pressure output, while the rigid steel frame construction provides durability for long-term heavy-duty performance. Additionally, its energy-efficient motor and hydraulic system help industries reduce electricity consumption without compromising productivity.

The Continuous Paper Baling Machine Auto Tying is also widely appreciated for its user-friendly interface and low maintenance requirements. Most models come with touch-screen control panels that allow operators to adjust pressure settings, bale length, tying cycles, and feeding speed. This level of customization helps industries optimize machine performance according to their waste type and desired bale density. The machine is designed with easily accessible maintenance points, ensuring quick servicing, lubrication, or part replacement. Furthermore, its strong wear-resistant compression chamber ensures long operational life, even with high-volume paper scrap. Safety features like emergency stop buttons, automatic shutdown on overload, and guarding around moving parts ensure operator security and compliance with industrial safety standards.

From a business perspective, investing in a continuous auto-tying paper baler brings immediate and long-term advantages. It increases production capacity, improves waste management efficiency, enhances workplace cleanliness, and reduces labor costs. With rising environmental standards and a global focus on recycling, companies using advanced baling machines gain a competitive edge by achieving faster processing speeds and higher-quality bales that meet industry norms. The machine also supports environmentally responsible operations by promoting recycling, reducing landfill load, and ensuring sustainable waste handling. Whether installed in a small recycling unit or a large material recovery facility, a continuous auto-tying paper baler delivers unmatched output consistency, long-term durability, and scalable performance as waste generation grows.

Our Blogs

-

PET Bottle Baling Machine Manufacturers in India for Recycling Plants

Read MoreJyoti Hydraulic is recognized as one of the trusted engineering…

-

Worm Gear Screw Jack Suppliers in India: Technical Specifications & Applications

Read MoreJyoti Hydraulic is recognized for delivering advanced industrial motion and…

-

Hydraulic Scrap Baling Press with Top Eject Technology – Jyoti Hydraulic

Read MoreJyoti Hydraulic is redefining how modern recycling and scrap management…